A new foundry concept

Assuming the challenges of the market Mettop and WeCo joined forces to get the best copper cooler through a standardized and safe production.

With the Know-How and control of the manufacturing process combined with the capabilities to design, simulate and optimize coolers for critical applications we started the development towards the perfect cooler.

In order to get the best performance and the longest lifetime of these coolers it is best to use copper tubing for the cooling circuits.

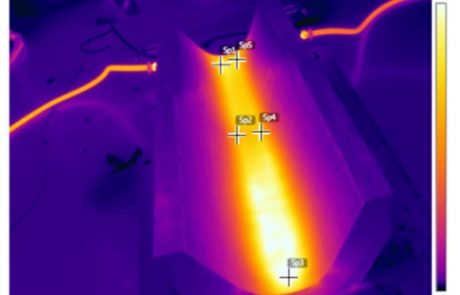

This entails the challenge of putting a thin metal structure into a surrounding with a large amount of liquid metal with a higher temperature then the melting point of the tube.

Therefore this procedure is currently only possible with smaller parts than approximately one ton, as the tube would otherwise melt or deform.

Larger parts are currently made with Monel tubing. This is an alloy which has a higher melting point and therefore the process of casting the coolers is easier as it will not be affected by the heat of the casting.

The product performance and the lifetime of these products, are however minor to those which are entirely made from copper while the manufacturing costs are significantly higher.

Additionally these elements are more difficult to recycle than elements purely made from copper. When they are re-melted the copper is contaminated with Nickel from the tube and the material cannot be re-used without refining. This results in higher energy consumption and lower end-of-life value.

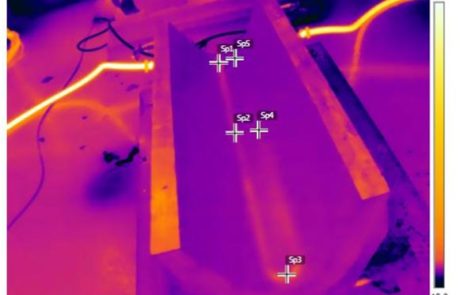

Therefore a method we developed which allows sufficient refrigeration of a copper cooling circuit during the casting process in order to prevent the melting or deformation of the tube.

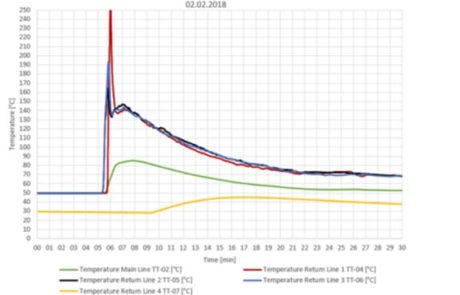

As the cooling with gases is not sufficient and the use of water is extremely dangerous in presence of liquid metals – the only viable option keeping work safety in mind, is to cool with an Ionic Liquid. These are man-made liquids which can be tailored in their characteristics in order to fit the application. In this case it is a cooling medium which can be used up to 250 °C and which is safe in handling and in case of direct contact to liquid metal.

Mettop holds the patent to the only non-corrosive and non-toxic Ionic Liquid specifically designed for metallurgical applications – the IL-B2001.

Therefore a co-operation between WeCo and Mettop has been formed in order to overcome the challenges of producing large cooling elements which are entirely made from copper in a safe way.

Since 2017 in our cooperation we have achieved: